Here you'll find whats instrumental in making the Bionicon System Unique

The Technology Behind Bionicon

Key Advancements

(c) 2006-2011 Zamph P/L & RideWERX all rights reserved!

BIONICON INNOVATIONS

Innovation is obligation

Riding a Bionicon means cultivating a culture of innovation.

Innovation means new, uncertain and exciting. Ground breaking innovations change both markets and

lives. We created such an innovation with our geometry adjustment system. To rest on our laurels would,

however, be impossible!

We nourish innovation as a culture which can be found in all of our products.

It isn’t just about the best inventions but rather to create and combine continuous developments in

every area of the bike. With an in-house development ratio of 60% of the whole bike Bionicon has the

highest degree of innovation depth in the entire bike industry. We see our bikes as integrated concepts

in which the interaction of individual parts can be permanently improved upon. Always within the ideals

of Bionicon lean engineering: simplicity, maintenance friendly and high performance.

BIONICON SYSTEM

The air slave unit and handlebar control button allow the rear to be lengthened as well as an infinitely variable adjustment of fork travel. The heart of a BIONICON

DOWNHILL

- centre of gravity shifted backwards

- up to 200mm suspension travel depending on the model

- upright position on bike

- perfect traction

- no "endo" feeling in steep terrain

- high straight line stability from relaxed head angle in downhill position and longer wheelbase.

UPHILL

- centre of gravity shifted forwards

- suspension fork travel adjustment without bottom bracket sinking

- upright position on bike

- perfect traction and reduced bob through K.P.P.

- front wheel stays firmly on the ground

- more effective breathing position

- 70 / 100 mm fork travel.

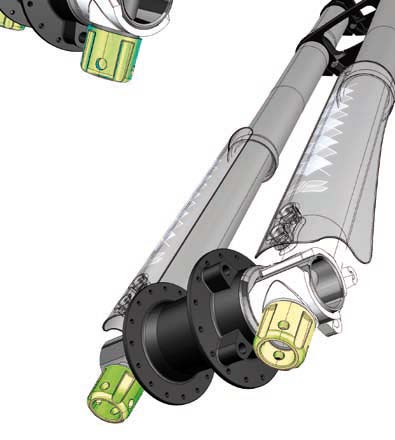

BIONICON F.I.T

45 degree direct bearing fit transforms front impact into pull force.

Our patented F.I.T. bearing technology tranfers impact and breaking loads subjected to the fork into tensile forces along the steerer tube. The split steerer tube construction can be built much lighter and also serves to adjust the headset bearing. The same technology is used for the Ironwood anbd Supershuttle swingarm.

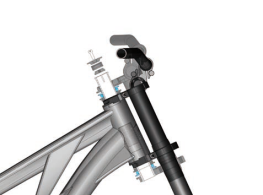

BIONICON TWIN-LOCK

135 degree infinite angle change: 10mm horizontal adjustment

Twin-lock allows an infinitely variable adjustment of the stem angle as well as two fixed stem length positions.

KINETIC PEDAL PLATFORM

The height adjustment of the rear shock also changes the chainline in relation to the swingarm, this reduces suspension bob without affecting bumb sensitivity.

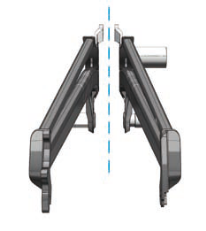

2- SIDE SWINGARM (Supershuttle and Ironwood Models)

Oversized 1 1/8 angular bearing fit, easy maintenance

The patented two-part swingarm construction combined with F.I.T. offers amazing rigidity and can almost be dismantled without tools to access and maintain the bearings.

3 - STEP

3mm fine tuning system.

3-Step allows you to choose a simple basic setup of bottom bracket height and head/seat tube angles.

Anti-twist hollow axel design; Quick open and close screw mechanism on 200mm Ironwood

Check out our Bionicon video's from YouTube and Vimeo - click here to see them!

What’s new at Bionicon?

The readers of the German magazine "bike“ voted us most innovative bike company worldwide for a third time in a row. We constantly bring innovations to the range bringing us closer to the perfect bike. How does product development work at BIONICON? Integrated product development doesn’t deal with single solutions but looks at complex inter-related processes. With suspension bikes levers, bearings and rear shock interact with the drivetrain, trail surface and rider. As engineers we assess each idea taking into account variables like function, design, weight, ergonomics, production costs, longevity and sustainability. We never forget our overriding philosophy: lean engineering – create the highest performance with the best possible serviceability and durability.

CAD, lab or trail testing?

We use FEM and kinematic simulation software to test the possibilities and consequences of every idea early in the development. Our test lab can assess suspension dynamics as well as simulating new product testing regulations. At the end of this process the most important test awaits: the rider, who will see if the bike works out on the trail. When the sun sets over Tegernsee many of us are still somewhere up a mountain, it’s no rarity to find a BIONICON prototype out on our house trails. These freaky machines and their creators always inspire animated discussions…

What does the future hold for BIONICON?

Whilst searching for the next "killer innovation“ we never forget to see if existing solutions are meaningful or can be improved on. Products and trends from other manufacturers and branches are always on our radar screens. You might find us playing bike polo or riding road bikes at the weekend. On days of fresh powder snow it can be deathly quiet in the R&D department before 11 am. We’ll be at work late at night making up hours whilst the snowcats groom the slopes. We want to go through life with an open mind and eyes, we want to live through innovation and never forget the ultimate aim: „build the bike, which doesn’t exist!“

Why is BIONICON superior?

- The unique BIONICON system changes front and rear suspension simultaneously.

- Uphill the rear suspension is bob free because we manipulate shock actuation, creating what we call KPP – Kinematic Pedal Platform.

- Bikes with just an adjustable fork cannot offer this benefit. Downhill increased fork travel, relaxed angles and active rear suspension inspire confidence.